Understanding the Dust Explosion Pentagon

Every combustible dust incident is the result of five critical factors coming together—a concept known as the Dust Explosion Pentagon. This article walks you through each side of the Pentagon, shows you real‐world mitigation strategies, and reveals how removing just one element can stop an explosion before it starts. Whether you’re an operations manager, safety officer, or maintenance technician, you’ll gain the insights and actionable steps needed to “break” the Pentagon and safeguard your facility.

In this post, we will cover:

- The Five Sides of the Dust Explosion Pentagon

- Dust Explosion Fuel—Grain Dust Characteristics

- Oxygen— Air & Ventilation Control

- Ignition Source— Hidden Heat and Spark Triggers

- Dispersion— Creating the Dust Cloud

- Confinement— Pressure Buildup & Secondary Dust Explosions

The Five Sides of the Dust Explosion Pentagon

A dust explosion only happens when all five sides of the Dust Explosion Pentagon are present at once. By recognizing and controlling each of these elements, you break the chain reaction and keep your facility safe.

Those five sides are:

Fuel

Fine combustible dust particles suspended in the air.

Oxygen

Atmospheric oxygen or other oxidizers in sufficient concentration.

Ignition Source

Heat, sparks, or hot surfaces that supply activation energy.

Confinement

Enclosed spaces that allow pressure to build and amplify an initial deflagration into a destructive explosion.

Click here to download the Dust Explosion Pentagon PDF.

Takeaway: Remove or control any one of these five conditions, and you prevent a high-pressure dust explosion.

Dust Explosion Fuel—Grain Dust Characteristics

Fuel refers to the fine, combustible particles that provide the energy for a rapid deflagration. In grain‐handling operations, that dust explosion fuel is grain dust—any material in the form of finely divided solid particles that, when dispersed in air, can ignite and explode.

Key Characteristics

- Particle Size– Dust under about 0.15 mm ignites most easily. The smaller the particle, the faster heat transfers and the quicker a flame front travels.

- Dust Layer Thickness– A settled layer as thin as 1/32″ (0.8 mm) can become explosive once re-entrained.

- Moisture Content- Dry dust (less than 10% moisture) ignites at lower energies; keeping grain above 14% moisture raises the Minimum Explosive Concentration (MEC) and helps prevent cloud formation.

Prevention Strategies

Rigorous Housekeeping

- Deploy Class II industrial vacuums daily on floors, equipment housings, and structural ledges—never dry sweep.

- Use “swipe tests” (white card held against surfaces) to detect hidden dust layers.

Dust Collection & Filtration

- Install enclosed conveyors and transfer points hooked to cartridge or baghouse collectors.

- Maintain and inspect filters monthly; replace cartridges before pressure differentials exceed manufacturer recommendations.

Moisture Management

- Integrate in-line moisture sensors at critical transfer and storage points.

- Use conditioning systems (e.g., drum humidifiers) to evenly raise grain moisture above 14 % before high-dust operations.

Access Control & Design

- Retrofit conveyor boots, discharge chutes, and dryer outlets with quick-release covers to simplify cleaning access.

- Seal cracks, seams, and bolt holes on equipment to eliminate dust “pockets.”

Takeaway: By reducing or eliminating combustible dust at its source, you “break” the Fuel side of the Pentagon—removing the very medium an explosion needs to propagate.

Oxygen— Air & Ventilation Control

Oxygen is the “combustion partner” that every dust cloud needs to ignite. In most grain-handling facilities, ambient air is sufficient to support a rapid flame front once fuel and dispersion conditions are met. While proper ventilation is essential for worker safety and dust removal, it can also inadvertently maintain or increase the oxygen level in confined areas, feeding a potential explosion.

Why Ventilation Matters

- Normal Airflow Can Fuel Explosions– Aeration fans and leaky ductwork introduce fresh oxygen that mixes with dispersed dust—creating an ignitable atmosphere.

- Blocked or Undersized Vents Increase Risk– NFPA 61 requires properly sized vents and flame-arresting devices to relieve pressure and prevent flashbacks in confined spaces.

Best Practices for Oxygen Control

Verify Vent Sizing & Maintenance

- Confirm bin vents and duct outlets comply with NFPA 61 sizing tables.

- Clean or replace filters quarterly to avoid airflow restrictions.

Install Flame Arrestors & Explosion Vents

- Use flame-arresting mesh or ceramic elements on vent inlets to stop flame propagation.

- Employ explosion relief vents to safely divert pressure peaks away from personnel and equipment.

Monitor Airflow Conditions

- Integrate differential-pressure gauges or airflow sensors to detect clogging.

- Set alerts for maintenance teams when pressure drop across filters exceeds safe thresholds.

Pro Tip: Place inexpensive clear-view inspection ports on vent housings. If dust buildup reduces visibility by more than 1 cm, schedule an immediate cleaning to restore safe oxygen pathways.

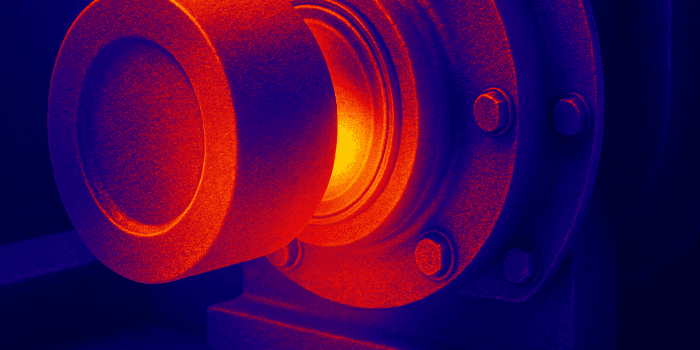

Ignition Source— Hidden Heat and Spark Triggers

The ignition source provides the activation energy that turns a dispersed dust cloud into a dust explosion. In grain facilities, everyday equipment and processes can harbor hidden hot spots or spark generators that are often overlooked.

Common Ignition Sources

- Overheated Bearings & Motors– Friction from misaligned or poorly lubricated bearings can exceed 500 degrees, igniting nearby dust deposits.

- Static Electricity & Friction Sparks– Grain moving at high speeds through metal chutes or across conveyor rollers generates static discharges capable of igniting fine dust.

- Hot Work & Welding– Grinding, cutting, or welding without proper dust controls creates airborne sparks that readily ignite combustible dust layers.

- Electrical Faults & Arcing– Damaged wiring, faulty switches, or loose electrical connections can arc and ignite dust clouds.

Prevention Tactics

- Infrared Technology: Schedule monthly IR scans to detect bearing or motor hotspots before they exceed safe thresholds.

- Grounding & Bonding: Install grounding straps and conductive flooring in transfer areas to dissipate static build-up safety.

- Hot-Work Permits & Controls: Enforce a strict permit system; designate spark-free zones, require fire watches, and prohibit grinding near settled dust.

Case Study:

In February 2008 at the Imperial Sugar refinery in Port Wentworth, Georgia, a static‐discharge spark from a conveyor drive motor ignited a fine sugar‐dust cloud, triggering a catastrophic explosion that killed 14 workers and injured 36 more. An infrared inspection would have revealed overheating in the motor bearings, and proper grounding and bonding could have dissipated static buildup—measures that would have interrupted the ignition side of the Dust Explosion Pentagon before disaster struck.

Takeaway: Hidden ignition sources are often the trigger for grain-dust blasts; proactive measures such as infrared thermography, grounding/bonding, and strict hot-work permitting can neutralize these risks before they ignite a dust explosion.

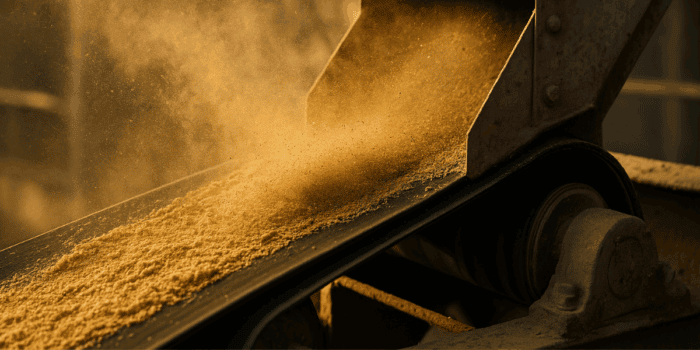

Dispersion— Creating the Dust Cloud

Dispersion is the process that suspends settled grain dust into air, creating the cloud required for a dust explosion. According to OSHA, dispersion of dust particles in sufficient quantity and concentration is one of the five critical elements in the Dust Explosion Pentagon.

How Dispersion Occurs

- Start-up & Shut-down Transients: Sudden changes in conveyor or elevator speed shake loose settled dust.

- Compressed-Air Cleaning Blasts: Blow-downs without containment aerosolize dust layers across wide areas.

- High-Velocity Material Transfers: Grain flowing through chutes and spouts agitates dust deposits.

Control Measures

- Vacuum-Style Cleaning: Use industrial vacuums with HEPA-rated filters instead of air blowers to remove dust at its source.

- Enclosed Transfer Points– Install ducted dust-collection hoods at conveyors, bucket-elevator boots, and dryer outlets.

- Gentle Startup Procedures– Ramp equipment speeds gradually to minimize vibration and dust agitation.

Pro Tip: Place portable dust monitors near transfer points. If airborne particulate counts exceed 2 mg/m³ during operation, pause and schedule a targeted vacuum cleaning before resuming.

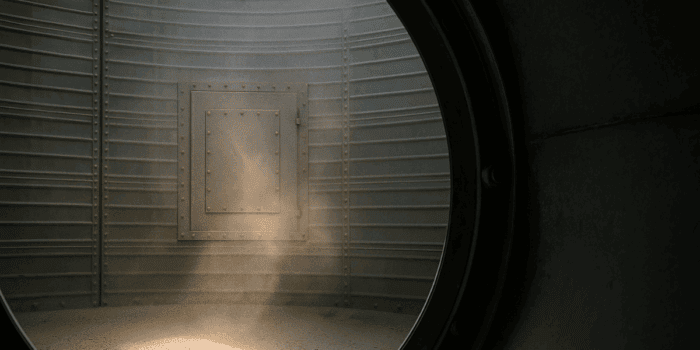

Confinement— Pressure Buildup & Secondary Dust Explosions

Confinement turns a deflagration into a devastating dust explosion by trapping expanding gases in enclosed spaces like silos, bins, conveyors, or buildings. When an initial flame front travels through a confined volume, pressure builds rapidly—often exceeding 100 psi—and can rupture walls or roofs, causing catastrophic secondary blasts.

How Confinement Amplifies Risk

- Enclosed Volume: A sealed silo or ductwork prevents expansion of heated gases, multiplying pressure and flame speed.

- Secondary Explosions: The first blast disturbs settled dust on walls, catwalks, and equipment, creating new clouds that ignite in rapid succession—a domino effect that accounts for up to 70% of total damage in a dust–explosion incident.

Mitigation Strategies

- Explosion Relief Vents– Install vents sized per NFPA 68 to rupture at designed pressures and safely disperse gases outside the structure.

- Chemical Suppression Systems– Deploy fast‐acting inhibitors that detect pressure rise and quench the flame front within milliseconds.

- Zoned Facility Layouts– Separate high‐risk equipment into dedicated rooms or compartments with fire‐resistant barriers and passive vent paths to limit confinement.

Pro Tip: Test relief vents annually by applying a controlled internal pressure (≈10 psi) and verifying panel failure at the specified rating—anything less indicates a blocked or weakened vent that could cost lives.

Conclusion

Preventing a dust explosion in grain facilities requires being aware of all five of the conditions—fuel, oxidant, ignition, dispersion, and confinement—and implementing layered controls that interrupt the chain reaction. By combining rigorous housekeeping, proper ventilation and relief vent design, ignition-source elimination, dust-collection systems, and robust emergency action planning, you create a comprehensive defense that dramatically reduces risk.

West Side Salvage is your partner in dust explosion prevention. We offer silo cleaning and inspection services that you can count on to prevent potential dust explosion disasters.

References

- OSHA. Combustible Dust: Hazard Recognition and Prevention (OSHA Pub. 3371). osha.gov

- Chrysalis Scientific. Lower LEL & Upper UEL Explosive Limits. chrysalisscientific.com

- U.S. Chemical Safety and Hazard Investigation Board. Final Report on Imperial Sugar Disaster (Static Discharge Ignition Findings). csb.gov

- OSHA. Guidance for Evaluating the Status of Respiratory Protection Programs: Combustible Dusts (OSHA Pub. 3791). osha.gov