Grain Dust Explosions: Understand the Causes, Prevention, and Safety

Grain dust explosions remain one of the deadliest hazards in agricultural and industrial operations. When fine dust particles become suspended in air and encounter a spark or hot surface, the result can be a rapid, high-pressure blast that shreds equipment, ignites secondary clouds, and risks lives.

Here is a summary of what we’ll cover:

- What Is a Grain Dust Explosion?

- Why Grain Dust Is So Dangerous

- Common Sources of Ignition in Grain Handling Facilities

- Where Explosions Typically Occur

- How to Prevent Grain Dust Explosions

- Responding to Dust Explosion Incidents

What Is a Grain Dust Explosion?

Grain dust explosions are rapid combustions that occur when fine grain particles ignite in confined spaces. These explosions can destroy equipment, injure workers, and halt operations. Understanding the conditions that make them possible is key to prevention.

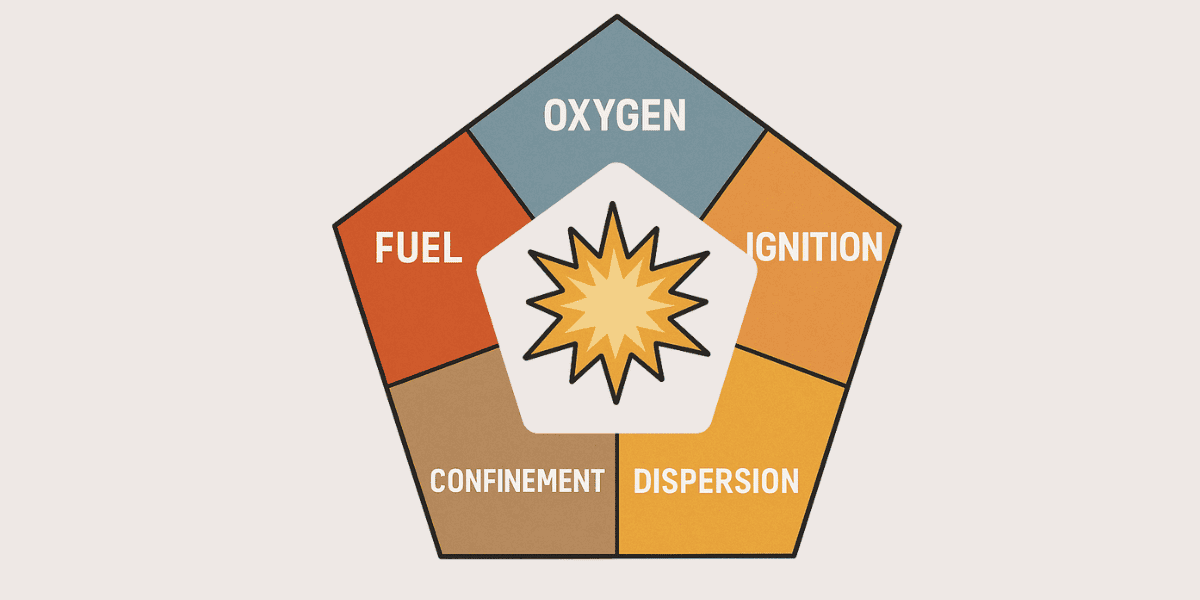

The Dust Explosion Pentagon

Unlike the traditional fire triangle, dust explosions require five elements to occur, forming what’s known as the Dust Explosion Pentagon:

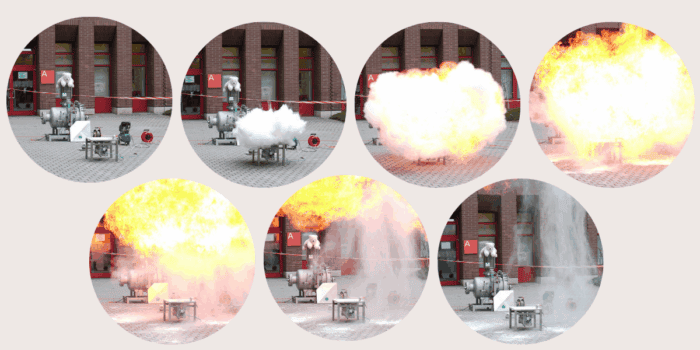

Watch a Dust Explosion Happen

Demonstration of an open-air dust explosion:

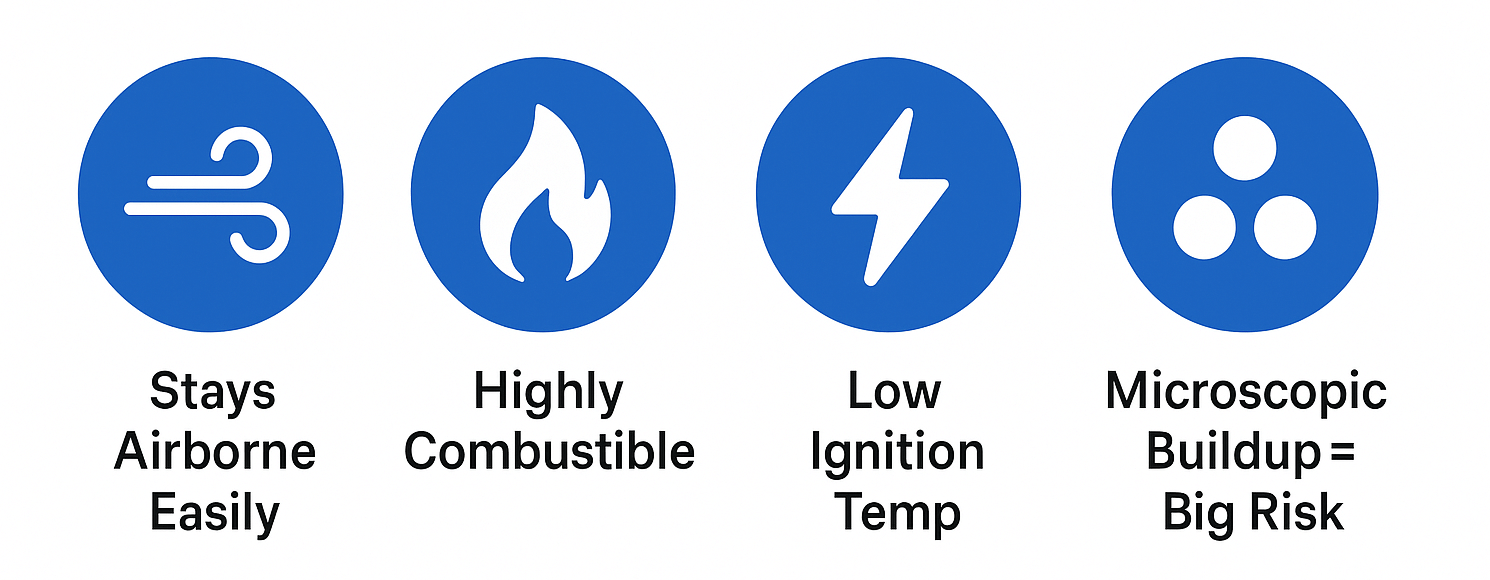

Why Grain Dust Is So Dangerous

Grain dust is more explosive than many operators realize. It’s lightweight, highly combustible, and can linger in the air with minimal disturbance. The fine particles generated during loading, unloading, or transfer operations can become airborne quickly—and in enclosed spaces, that creates a perfect ignition scenario. Just a small concentration of suspended dust is enough to trigger an explosion.

Characteristics That Make Grain Dust Explosive:

- Fine particle size allows it to stay airborne

- Low ignition temperature makes it easily flammable

- Accumulates in hard-to-see areas like rafters and ducts

- Small quantities create large-scale explosions in confined areas

Did You Know: Just 1/32 inch of dust (the thickness of a paperclip) evenly spread on surfaces is enough fuel to cause a devastating explosion.

Common Sources of Ignition in Grain Handling Facilities

Even a small spark can be catastrophic in the right conditions. While grain dust itself is the fuel, ignition is the trigger—and these sources are often hiding in plain sight. Many dust explosions are caused by everyday equipment and processes that generate heat or friction.

Here are some of the most common ignition sources found in grain handling operations:

Overheated Bearings and Motors

Equipment that isn’t regularly inspected can overheat, creating hot surfaces or friction sparks.

Electrical Malfunctions

Exposed wiring, short circuits, and static electricity can easily ignite airborne dust.

Welding or Cutting

Avoid hot work like welding when combustible dust is nearby.

Friction from Moving Parts

Misaligned belts, chains, or mechanical components can spark if not properly maintained.

Open Flames or Pilot Lights

Even small flames in dryers or heaters can ignite airborne dust particles.

Spontaneous Combustion

Dust accumulation on hot surfaces can sometimes smolder and ignite without an external spark.

Takeaway: Routine maintenance, inspections, and awareness are essential to reducing these ignition risks and preventing catastrophe.

Where Explosions Typically Occur

Grain dust explosions often originate in areas where dust accumulates and airflow is limited.

Common high-risk zones include:

- Grain Elevators – Tall, enclosed structures where dust accumulates and friction from machinery can spark ignition.

- Silos and Storage Bins – Often confined, poorly ventilated, and subject to material flow blockages that disturb settled dust.

- Bucket Wlevators and Conveyors – Combine movement, friction, and dust in tight spaces.

- Dust Collection Systems – Ironically, these systems concentrate dust and, without proper venting or monitoring, can cause secondary explosions.

- Transfer Points and Loadout Areas – Airborne dust is most concentrated during movement, especially in dry conditions.

Outside the Grain Industry

Dust explosions are not limited to agriculture. Industries that process organic materials, metals, plastics, and chemicals are also at risk.

- Food production (sugar, flour, starch)

- Woodworking (sawdust, sanding operations)

- Textile manufacturing (cotton, lint)

- Metalworking (aluminum, magnesium dust)

- Plastics and rubber processing

- Coal and paper manufacturing

Takeaway: These areas often involve confined spaces and moving machinery—perfect conditions for suspended dust and sparks to meet.

How to Prevent Grain Dust Explosions

Prevention starts with proactive safety measures that reduce the risk of ignition and accumulation.

Click here to download our Dust Explosion Prevention Checklist.

Housekeeping & Dust Control

- Regularly clean surfaces, rafters, and machinery.

- Use explosion-proof vacuums rather than compressed air to avoid further dispersion.

- Keep floors, ledges, and ducts free of dust buildup.

Ventilation Systems

- Maintain proper ventilation to reduce airborne dust concentrations.

- Inspect filters, ducts, and fans to ensure they’re operating efficiently.to avoid further dispersion.

Explosion Suppression Systems

- Install explosion vents or suppression devices in high-risk areas.

- Follow NFPA 61 guidelines for proper design and spacing.

- Use spark detection systems that trigger shutdowns when hazards are detected.

Takeaway: Regularly clean dust buildup on beams, catwalks, ducts, and equipment. Use explosion-proof vacuums and ensure proper dust collection systems are maintained.

Responding to Dust Explosion Incidents

If an explosion occurs, response time is critical. First, isolate the area and ensure all personnel are accounted for. Then, begin damage assessment and cleanup. Engaging a professional recovery team like West Side Salvage can reduce downtime, limit secondary hazards, and salvage materials.

Have an Emergency Action Plan

Even the best prevention controls can’t eliminate all risk. A robust Emergency Action Plan (EAP) ensures your team can respond swiftly and safely if a dust explosion occurs.

Detection & Alarm Systems

- Install multi-sensor alarms (pressure rise, flame, heat) to trigger immediate alerts.

- Integrate with facility SCADA for centralized monitoring and automatic shutdown of conveyors and fans.

Evacuation Procedures

- Map and mark clear escape routes with illuminated signage and backup lighting.

- Conduct quarterly evacuation drills, timing each phase from alarm to muster point.

Rescue Resources & Equipment

- Stock grain-rescue tubes, portable airway systems, and fire-resistant blankets.

- Train in-house responders and coordinate with local emergency services on confined-space rescue protocols.

Communication & Command

- Define an incident command structure with pre-assigned roles (Incident Commander, Safety Officer, Communications Lead).

- Use two-way radios or mass-notification apps to relay real-time updates and instructions.

Takeaway: West Side Salvage is offering free reviews of Emergency Action Plans (EAP)! With decades of real-world experience responding to grain emergencies, we know what works and what doesn’t.

Work With a Trusted Recovery Partner

At West Side Salvage, we’ve seen firsthand the damage grain dust explosions can cause. Our team specializes in emergency response and disaster recovery for grain storage facilities. From explosion cleanup to commodity salvage, we help you recover quickly and minimize losses.

Don’t wait for a disaster—plan ahead and stay protected. If an explosion occurs, contact West Side Salvage for a rapid, experienced response. We offer silo cleaning and inspection services that you can count on to prevent potential dust explosion disasters.

References

- Occupational Safety and Health Administration. (n.d.). Combustible dust: Hazard recognition and prevention (OSHA Publication 3371). U.S. Department of Labor. https://www.osha.gov/sites/default/files/publications/3371combustible-dust.pdf

- U.S. Environmental Protection Agency. (n.d.). What is a HEPA filter? https://www.epa.gov/indoor-air-quality-iaq/what-hepa-filter

- Dust Explosion. (2017, August 9). Dan Leuthner [Video]. YouTube. https://youtu.be/HbMR-CbFLNg

- Wikipedia contributors. (n.d.). Dust explosion. In Wikipedia, The Free Encyclopedia. https://en.wikipedia.org/wiki/Dust_explosion#Mechanism

- Inductive Automation. (n.d.). What is SCADA? https://inductiveautomation.com/resources/article/what-is-scada