Grain Spoilage & Contamination: Causes, Signs, and Solutions

Grain spoilage and contamination are among the most costly risks for farmers and grain handlers. A single pocket of spoiled corn or soybeans can spread quickly, leading to thousands of bushels lost, and with it, lost revenue. In fact, millions of bushels are ruined each year in the U.S. due to improper storage, moisture problems, pests, or handling issues.

Do You Own A Silo/Bin?

West Side Salvage specializes in emergencies & commodity salvage of foods, grain, etc. Our team works to help prevent emergencies as well through scheduled inspections and cleanouts.

Fast Facts About Spoiled Grain

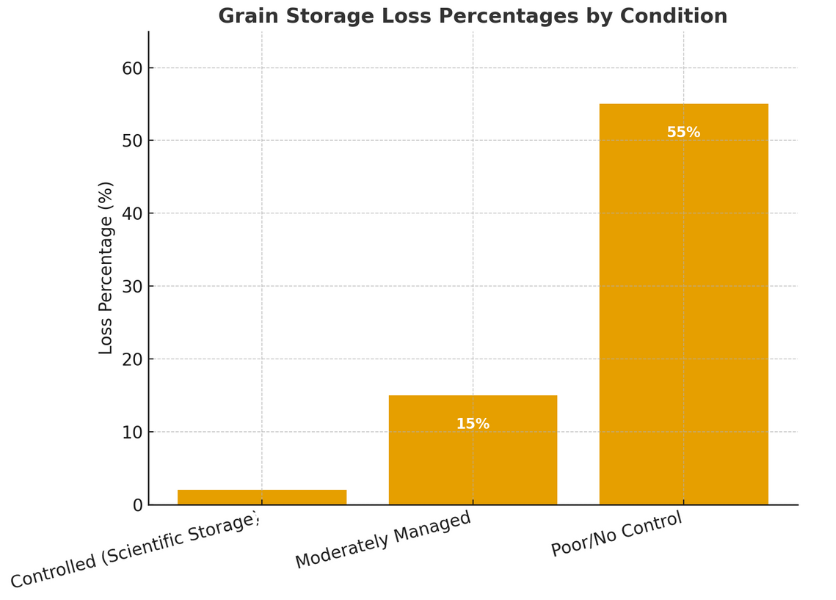

- Losses in storage alone may account for 10–20% of stored grain in many systems.

- In systems without good technical controls, loss can escalate to 50–60%.

- In well-managed systems, losses can be held to 1–2% per storage cycle.

- Insect and pest damage can dominate weight losses: in stored grain settings, it’s estimated that pests cause a large share of losses (some estimates say 10–60% in various contexts).

Causes of Grain Spoilage and Contamination

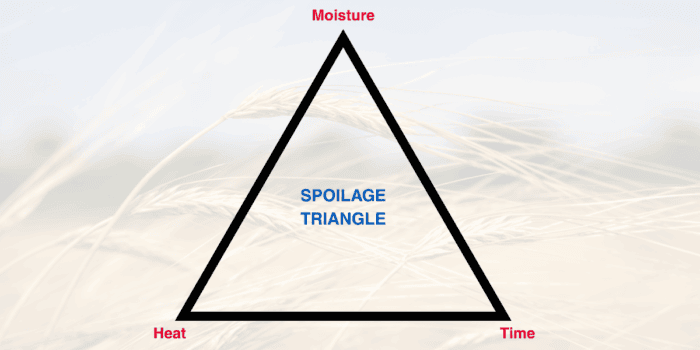

Moisture and Poor Aeration

High moisture is the primary gateway for mold and microbial activity. Without proper airflow, condensation forms, creating “hot spots” under layers of grain. Over time, these pockets spread.

Temperature Fluctuations

Seasonal or daily temperature swings cause the grain mass to expand or contract, leading to “sweating” and crusting. These crusted zones trap heat and moisture, exacerbating spoilage.

Insects and Pests

Stored-grain pests (weevils, beetles, mites, rodents) do more than consume grain: they contaminate it with frass, bodies, and excreta, introduce heat in hotspots, and open pathways for mold to invade.

Some reports assert that pests are responsible for 10% to 60% of post-harvest weight loss in stored grain, particularly in less controlled environments.

Foreign Materials and Dust

Broken kernels, fines, chaff, dust, and debris are prime locales for mold and bacterial growth. They can block airflow pathways and lead to uneven drying or moisture gradients.

Improper Handling

Damage (cracking, broken kernels) from rough handling, over-drying, or equipment misalignment lowers resistance to spoilage. Cracks allow moisture and microbes to invade.

Warning Signs of Spoiled or Contaminated Grain

Detecting problems early can mean the difference between saving a bin and losing it entirely.

Watch for these red flags:

- Musty, sour, or chemical odors

- Visible mold, discoloration, or slimy kernels

- Clumped or crusted grain surfaces

- Temperature probes indicating hot spots

- Evidence of insects, insect shells, or rodent droppings

Prevention Strategies for Spoilage

Moisture Control

- Dry grain to safe moisture thresholds before binning.

- Avoid mixing wetter grain with dryer grain unless blended uniformly.

- Monitor moisture content over time, especially after environmental changes.

Aeration and Cooling

- Use fans to circulate air and keep temperatures uniform.

- Plan aeration schedules when outside air conditions (temperature, humidity) are favorable.

- Even minor airflow helps prevent condensation and “sweating.”

Routine Monitoring

- Probe the grain regularly for moisture and temperature gradients.

- Keep records over time to identify trends.

- Address early deviations promptly.

Bin Maintenance

- Clean bins before filling to remove residual fines, broken kernels, or foreign debris.

- Repair any leaks, seals, doors, or vents.

- Make sure bin design doesn’t allow water intrusion (from rain, snow, etc.).

Pest Management

- Seal bin entries, use screening or insect barriers.

- Apply fumigation or approved pesticides when needed (following legal and safety guidelines).

- Monitor for early pest activity before infestations take off.

Case Study: In one scenario, a bin was filled soon after harvest without sufficient drying. Within weeks, internal hot spots developed. By the time the farmer smelled off-aroma, nearly 20–25% of the bin’s grain was unsuitable, a loss equivalent to thousands of bushels. This kind of outcome tracks with the higher-end loss estimates seen in poor storage systems. (This example aligns with broader research showing that, in less controlled systems, storage losses of 20–50% aren’t uncommon.)

What To Do if Spoilage or Contamination Occurs

Even with the best precautions, spoilage can still happen. When it does, time is critical:

- Segregate affected grain to prevent contamination of clean product.

- Avoid mixing spoiled grain with fresh storage.

- Document the issue for insurance claims.

- Contact a salvage company if large volumes are compromised. Professional help can minimize loss and recover usable grain.

Conclusion

Grain spoilage and contamination are preventable threats, but they require vigilance. By controlling moisture, monitoring conditions, and keeping bins clean, farmers can protect their harvests and reduce risk.

When spoilage does occur, swift action is key. At West Side Salvage, we specialize in grain salvage, spoilage response, and emergency bin services. If spoilage or contamination is threatening your operation, don’t wait, contact us today to minimize losses and recover as much as possible.