Silo Fires and Explosions: Why Do They Happen?

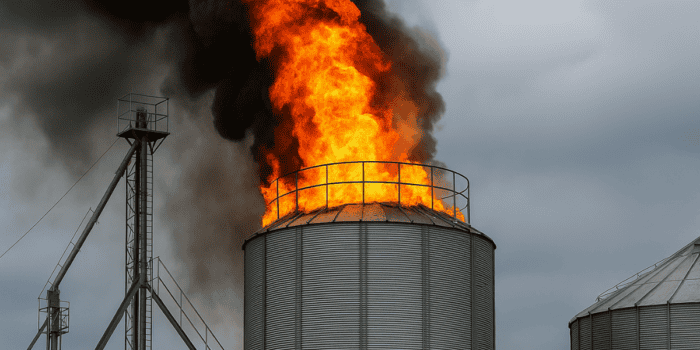

Silo fires and grain bin fires can start quietly and end catastrophically. Trapped heat, moisture, or dust can turn stored grain into fuel for a dangerous blaze or explosion. Each year, dozens of incidents across the U.S. cause major crop loss, equipment damage, and even injuries or fatalities.

In this guide, you’ll learn:

- What causes silo and grain fires

- How to spot early warning signs

- Steps to prevent grain fires and explosions

- What to do if a grain fire starts

At West Side Salvage, we help farmers and facilities recover from grain bin fires. This guide draws on that experience to help you stay safe and protect your operation.

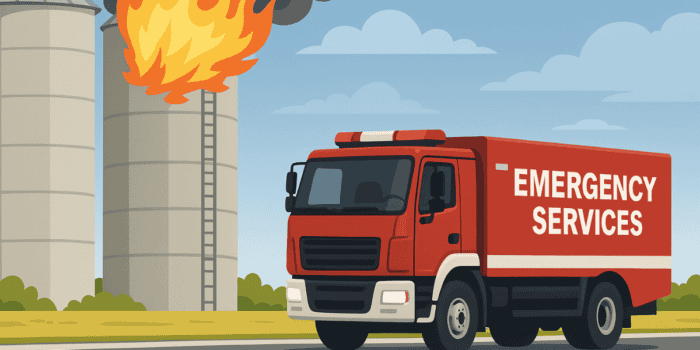

Experiencing A Grain Fire?

West Side Salvage deploys a team immediately to work with local fire departments to extinguish and dig out the fire using our customized equipment. We have a 100% Success Rate in Extinguishing Fires.

Understanding Silo & Grain Fires

Silo fires are dangerous fires that occur in silos, which can be caused by a variety of factors, including improper moisture levels in stored material, ignition of combustible dust, and the accumulation of toxic gases from fermentation. Preventing silo fires involves maintaining proper moisture content in stored material, controlling dust, ensuring good ventilation, and performing regular equipment inspections and maintenance.

What They Are

A silo fire or grain bin fire happens when heat builds up inside stored grain or silage until ignition occurs. It often begins deep in the pile, hidden from view, where moisture, microbial activity, or friction raise temperatures above safe levels.

Why It Happens

- Moisture and heat: Wet grain ferments, producing heat and gases.

- Dust: Fine grain dust can ignite from static electricity or equipment sparks.

- Poor airflow: Without ventilation, heat pockets form and can smolder for days.

- Mechanical issues: Hot bearings or metal friction can trigger ignition.

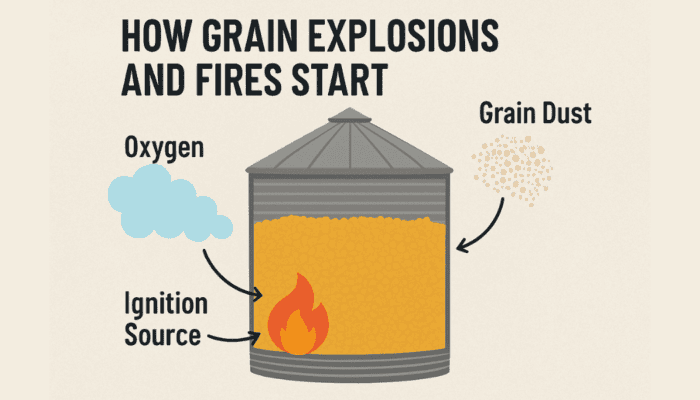

How It Differs From An Explosion

A silo fire burns slowly inside the stored material. A grain dust explosion occurs when fine particles become airborne, mix with oxygen, and ignite, causing a pressure wave and structural damage.

Why It Matters

Even a small smoldering fire can destroy grain quality, weaken the structure, and create explosion hazards if disturbed. Early recognition is critical.

Takeaway: Silo and grain fires rarely start big; they start hidden. Recognizing how and why they form is the first step in preventing disaster.

What Causes Silo Fires and Explosions?

While these incidents might seem sudden, they often build slowly due to overlooked warning signs or poor storage conditions.

Common Causes Include

- Dust Accumulation: Flammable dust particles settle in the silo and form a combustible cloud. If disturbed and ignited, this cloud can cause a dust explosion.

- Static Electricity: Equipment failure or malfunction can create sparks or static electricity, igniting the dust cloud.

- Hot Spots: These happen when heat builds up in specific areas. This can be due to friction, decomposition, or fermentation of stored materials. These concentrated areas of heat can ignite combustible materials.

- Poor Ventilation: Bad airflow in silos lets heat, moisture, and flammable gases build up. This creates a perfect environment for fires.

- Spontaneous Combustion: This happens when stored materials, such as grains or organic matter, create heat naturally. This can occur through processes like decomposition or fermentation. If the heat does not dissipate, it can build up to the point of ignition.

- Improper Cleaning and Maintenance: If the silo is not cleaned often, dust can build up inside. This greatly increases the risk of explosions.

Takeaway: Silo fires and explosions are typically the result of a dangerous combination of heat, moisture, and combustible materials trapped in confined spaces.

Warning Signs and Early Detection of Grain Fires

Silo and grain fires often start deep inside the pile, where you can’t see the problem until it’s serious. Spotting early warning signs can help stop a smoldering fire before it spreads or triggers an explosion.

Common Warning Signs

- Unusual odors: A burnt, musty, or caramel-like smell can signal overheating grain.

- Steam or smoke: Even faint wisps from vents or seams indicate smoldering.

- Hot surfaces: Warm or discolored bin panels can mean trapped heat inside.

- Condensation: Moisture on the roof or walls suggests temperature imbalance.

- Hard crusts or clumps: Grain that feels compacted or crusted may be cooking beneath the surface.

- Unexplained insects or mold growth: Both can thrive in hot, damp spots that precede combustion.

Detection Methods

- Temperature cables or probes: Track heat pockets throughout the grain mass.

- Infrared cameras: Detect surface temperature changes before smoke appears.

- Gas monitoring: Rising carbon monoxide (CO) levels are an early sign of smoldering.

- Regular inspections: Monthly or seasonal checks help catch early heat buildup.

Early Detection Checklist

- Record temperature readings regularly

- Inspect vents and access points for smoke or steam

- Monitor CO or CO₂ if sensors are available

- Check grain condition during each load-in or transfer

- Keep logs to identify temperature trends over time

Takeaway: The sooner you find a problem, the easier it is to fix. Continuous monitoring and attention to small changes are the best defenses against grain fires.

Prevention and Mitigation Best Practices

Preventing a silo or grain bin fire starts long before the first spark. The key is to control the conditions that let heat, dust, or gas build up in the first place.

Grain Fire Prevention Priorities

- Keep grain dry and uniform

- Maintain steady airflow

- Control dust and debris

- Inspect and maintain equipment regularly

- Implement monitoring technology to catch issues early

- Train staff on fire and explosion response

1. Control Moisture and Temperature

Excess moisture is the most common trigger for grain fires. Wet grain ferments, generating heat and gases. If that heat cannot escape, it builds until the grain begins to smolder.

- Harvest grain at the recommended moisture level (typically below 15% for corn).

- Use grain dryers to reduce internal moisture before storage.

- Monitor silage packing density and oxygen exclusion to limit fermentation heat.

2. Maintain Proper Ventilation

Proper airflow prevents heat buildup and reduces the risk of both fires and dust explosions.

- Install and maintain a consistent aeration system.

- Avoid introducing air suddenly into a suspected fire — it can trigger ignition.

- Ventilation should be used proactively, not reactively during a fire.

3. Reduce Dust and Residue

Dust is a major explosion risk. Fine grain dust suspended in the air becomes extremely flammable in confined spaces.

- Regularly clean catwalks, beams, and bin interiors.

- Install dust collection systems in handling areas.

- Avoid overfilling silos and spilling material near exhaust fans.

4. Inspect Electrical and Mechanical Systems

Small equipment failures can have big consequences if they introduce heat or sparks into the silo.

- Inspect electrical systems, fans, and augers for wear or exposed wiring.

- Replace seals, check grounding systems, and clean vents.

- Schedule a full structural inspection annually, especially before peak storage seasons.

5. Monitor Continuously

Technology can detect the early signs of combustion before you see or smell anything.

- Install temperature probes or infrared sensors inside silos.

- Monitor CO and CO₂ levels, which rise during microbial activity or combustion.

- Log readings regularly and investigate sudden spikes.

6. Emergency Readiness

The best equipment won’t help if your team doesn’t know how to respond safely.

- Train workers on early warning signs and safe silo entry procedures.

- Establish a no-entry policy during suspected silo fires.

- Create an emergency action plan that includes fire department contact protocols and safe evacuation routes. (request an EAP review)

Takeaway: Proactive prevention is the most effective way to reduce fire and explosion risk in your silos.

What to Do During a Grain Fire or Explosion

If you suspect a grain bin or silo fire, act quickly and safely. Fires inside grain storage are extremely dangerous and require professional response.

Step-by-Step Response

- Call 911 immediately.

Alert your local fire department and report a possible grain or silo fire. - Contact the West Side Salvage 24/7 emergency line at 844-246-2234.

Our 24-hour team will coordinate with local firefighters and begin deployment. - Do not enter or open the bin.

Opening hatches or doors can feed oxygen to the fire and trigger an explosion. - Shut down fans and equipment.

Stop all aeration, augers, and conveyors to prevent spreading heat or flame. - Wait for professional responders.

When our team arrives, we work directly with local firefighters to assess the situation and locate the fire’s core. - Allow West Side Salvage to remove burning grain.

Our proven method involves physically removing burning grain to eliminate the heat source completely, ensuring a full extinguishment and faster recovery.

Key Safety Reminders

- Never attempt to fight a silo fire internally.

- Avoid pumping gases or water into the bin; these rarely reach the fire’s core.

- Keep all personnel clear until professionals confirm stability.

Takeaway: The safest and fastest way to stop a grain bin or silo fire is to call 911, then West Side Salvage. Our hands-on removal method achieves complete extinguishment without risking further damage or smoldering.

Conclusion

Silo and grain fires rarely start big. They begin with small pockets of heat, moisture, or dust that go unnoticed until it’s too late. Acting fast and knowing who to call can make all the difference between a controlled recovery and a total loss.

If you ever suspect a silo or grain bin fire:

- Call 911 immediately.

- Then contact West Side Salvage’s 24-hour emergency line at 844-246-2234.

Our team works side by side with local fire departments to locate the heat source, remove burning grain, and fully extinguish the fire. This proven method restores safety faster and minimizes both damage and downtime.

At West Side Salvage, we’ve helped resolve grain bin and silo fires across the country with 100% success. From emergency response to post-fire recovery, we bring the experience, equipment, and precision needed to protect your operation and get you back on track safely.