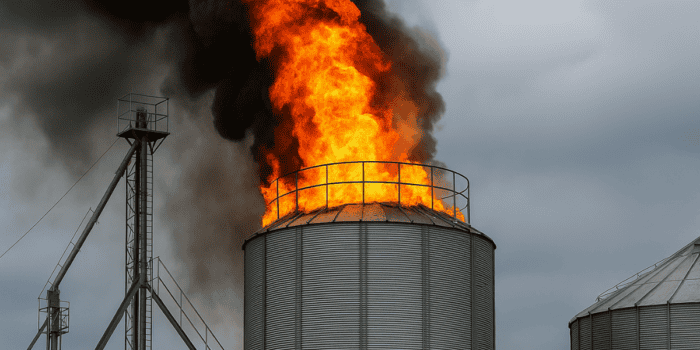

Silo Fires and Explosions: Why Do They Happen?

Silo fires and explosions are devastating events that can lead to significant damage, loss of life, and financial setbacks. Understanding the causes of these incidents is crucial for preventing them. At West Side Salvage, we specialize in reducing these risks by offering expert silo cleaning and maintenance services. Here’s what you need to know about the causes of silo fires and explosions—and how regular cleaning can help prevent them.

Here is a summary of what we will cover:

- What Are Silo Fires and Explosions?

- What Causes Silo Fires and Explosions?

- Signs That Your Silo May Be at Risk

- Prevention Tips for Silo Fires and Explosions

- What to Do if a Silo Fire or Explosion Happens

What Are Silo Fires and Explosions?

Silo fires and explosions are hazardous events that can occur in industrial silos. These incidents are dangerous and often are a result from the buildup of dust or other flammable materials inside of the silo. These emergency situations pose serious potential consequences including loss of life, property damages, production downtime, and environmental harm. It is important to understand what silo fires and explosions are as well as the threat they pose in order to also understand how to prevent these catastrophic events.

Silo Fires

A silo fire typically begins deep inside stored grain or silage when internal temperatures rise due to microbial activity, fermentation, or trapped moisture. The fire smolders slowly, often with little or no visible smoke or flame, and can go undetected for days. Because oxygen is limited inside a closed silo, these fires burn under compression and produce gases like carbon monoxide and methane.

Silo Explosions

Silo explosions, on the other hand, occur when flammable gases or fine dust particles ignite suddenly—often after someone unknowingly introduces oxygen into the system by opening a hatch or starting a ventilation fan. If the fire has already been smoldering inside, this sudden air flow can trigger a violent deflagration or even a full structural blast.

The Hidden Danger

What makes these events especially dangerous is their unpredictability. A routine inspection can unintentionally turn a silo fire into an explosion. Grain dust, in particular, becomes highly explosive when suspended in the air and ignited—making older or poorly ventilated silos especially vulnerable.

Takeaway: Silo fires and explosions are not just rare accidents—they’re often silent, slow-building events with explosive potential.

What Causes Silo Fires and Explosions?

While these incidents might seem sudden, they often build slowly due to overlooked warning signs or poor storage conditions. Understanding the root causes is essential for prevention—and for protecting both lives and property on farms and in grain-handling facilities.

Here are some of the causes:

- Dust Accumulation: Flammable dust particles settle in the silo and form a combustible cloud. If disturbed and ignited, this cloud can cause a dust explosion.

- Static Electricity: Equipment failure or malfunction can create sparks or static electricity, igniting the dust cloud.

- Hot Spots: These happen when heat builds up in specific areas. This can be due to friction, decomposition, or fermentation of stored materials. These concentrated areas of heat can ignite combustible materials.

- Poor Ventilation: Bad airflow in silos lets heat, moisture, and flammable gases build up. This creates a perfect environment for fires.

- Spontaneous Combustion: This happens when stored materials, such as grains or organic matter, create heat naturally. This can occur through processes like decomposition or fermentation. If the heat does not dissipate, it can build up to the point of ignition.

- Improper Cleaning and Maintenance: If the silo is not cleaned often, dust can build up inside. This greatly increases the risk of explosions.

Takeaway: Silo fires and explosions are typically the result of a dangerous combination of heat, moisture, and combustible materials trapped in confined spaces.

Signs That Your Silo May Be at Risk

Warning signs provide key indicators that a silo may be at risk or a fire or explosion. If you notice any of the following signs, you should act as soon as possible

Physical Indicators

- Unusual Smells: A burnt, musty, or acrid odor near the silo may signal smoldering organic material.

- Heat Radiating from the Silo Walls: Use infrared thermometers to detect surface hotspots.

- Discoloration of Silo Surfaces or Metal Components: Warping or soot marks may suggest internal combustion.

- Smoke or Gas Venting: Even a thin plume from the top or side vents could be a late-stage warning.

Monitoring and Detection Signs

- Elevated Internal Temperatures: If temperature probes inside the silo show sudden or rising heat, it could indicate microbial activity or combustion.

- Carbon Dioxide (CO₂) or Carbon Monoxide (CO) Spikes: These gases are early byproducts of decomposition or smoldering fires.

- Pressure Buildup or Gas Hissing: An increase in internal pressure, especially if venting systems are blocked, may signal a brewing fire.

- Blockages or Crusting Near Discharge Chutes: Fires can cause compaction and restrict material flow.

Takeaway: If you notice a sudden increase in dust levels or a decrease in airflow, it’s time to schedule a professional cleaning. Don’t wait for a minor issue to turn into a catastrophe.

Prevention Tips for Silo Fires and Explosions

Most silo fires and explosions are preventable. By controlling moisture, managing airflow, and maintaining clean equipment, operators can greatly reduce the risk of ignition. Whether you’re storing silage, grain, or feed, these prevention strategies are essential for protecting your facility, your team, and your inventory.

Maintain Proper Moisture Levels

Moisture is one of the leading causes of silo fires. Wet grain or silage can heat up through microbial activity, eventually triggering spontaneous combustion.

- Harvest grain at the recommended moisture level (typically below 15% for corn).

- Use grain dryers to reduce internal moisture before storage.

- Monitor silage packing density and oxygen exclusion to limit fermentation heat.

Use Controlled Aeration and Ventilation

Proper airflow prevents heat buildup and reduces the risk of both fires and dust explosions.

- Install and maintain a consistent aeration system.

- Avoid introducing air suddenly into a suspected fire — it can trigger ignition.

- Ventilation should be used proactively, not reactively during a fire.

Prevent Dust Accumulation

Dust is a major explosion risk. Fine grain dust suspended in the air becomes extremely flammable in confined spaces.

- Regularly clean catwalks, beams, and bin interiors.

- Install dust collection systems in handling areas.

- Avoid overfilling silos and spilling material near exhaust fans.

Monitor Temperature and Gas Levels

Technology can detect the early signs of combustion before you see or smell anything.

- Install temperature probes or infrared sensors inside silos.

- Monitor CO and CO₂ levels, which rise during microbial activity or combustion.

- Log readings regularly and investigate sudden spikes.

Perform Routine Maintenance and Inspections

Small equipment failures can have big consequences if they introduce heat or sparks into the silo.

- Inspect electrical systems, fans, and augers for wear or exposed wiring.

- Replace seals, check grounding systems, and clean vents.

- Schedule a full structural inspection annually, especially before peak storage seasons.

Train Your Team in Fire Safety Protocols

The best equipment won’t help if your team doesn’t know how to respond safely.

- Train workers on early warning signs and safe silo entry procedures.

- Establish a no-entry policy during suspected silo fires.

- Create an emergency action plan that includes fire department contact protocols and safe evacuation routes.

Takeaway: Proactive prevention is the most effective way to reduce fire and explosion risk in your silos.

What to Do If a Silo Fire or Explosion Occurs

Silo fires and explosions are high-risk emergencies. They are unpredictable, difficult to extinguish, and extremely dangerous to approach. If you suspect a fire or experience an explosion, it’s critical to avoid impulsive actions that could escalate the situation.

Follow these steps to protect your team and minimize damage:

1. Do Not Enter the Silo

Never attempt to enter a silo that may be on fire. Confined space hazards combined with low oxygen levels, toxic gases, and the potential for flare-ups make this a life-threatening environment.

- Do not break crusted grain to investigate.

- Avoid opening side hatches or manways.

- Do not initiate ventilation unless directed by fire response professionals.

2. Contact Emergency Services Immediately

Time is critical when responding to a silo fire. Call 911 or your local fire department and inform them it’s a suspected confined-space or agricultural fire.

- Clearly describe the type of structure (grain bin, tower silo, etc.).

- Alert them to the presence of dust, gas buildup, or suspected smoldering.

- Request a department experienced in agricultural or industrial fire response, if possible.

- You can also call West Side Salvage at this time as we offer emergency response services.

3. Evacuate and Secure the Area

Keep workers and bystanders at a safe distance, and prevent access to the site until the situation is fully evaluated.

- Silo explosions can occur even hours after the initial fire.

- Evacuate the area based on fire department guidance.

- Monitor the structure for signs of structural failure or collapse.

4. Avoid Venting or Cooling the Silo

Introducing air into a sealed, smoldering silo can trigger combustion or a dust explosion. Unless you are working under the guidance of fire professionals:

- Do not turn on fans.

- Do not open the top hatch.

- Avoid applying water through the roof — it may spread the fire or cause collapse.

5. Contact a Professional Silo Salvage or Recovery Team

Once emergency services have secured the scene, work with a specialized salvage company like West Side Salvage to assess the damage and recover any remaining product safely.

- Our team is trained in confined space safety, grain removal, and post-fire recovery.

- We use specialized vacuum systems and tools to minimize structural stress.

- Salvaging viable grain after a fire can help reduce financial losses.

Takeaway: Your response during the first hours of a silo fire can make the difference between containment and catastrophe.

Conclusion

Silo fires and explosions are not only dangerous—they’re often preventable. What begins as a slow smolder caused by heat, moisture, or microbial activity can rapidly turn into a violent blast when oxygen is introduced. Without proper moisture control, cleaning, and monitoring systems, even well-managed operations can face devastating losses.

At West Side Salvage, we’ve responded to hundreds of grain storage emergencies. Our team specializes in silo fire response, grain recovery, and structural cleanup—always with a focus on safety, speed, and salvaging as much value as possible.

Whether you’re dealing with a suspected fire or simply want to prepare your operation with an emergency plan, we’re here to help.

Contact West Side Salvage to schedule a silo inspection or request emergency assistance.