Damaged Grain in the US: Costs, Causes & Prevention

Damaged grain is a widespread and costly issue in U.S. agriculture. From moisture-related spoilage to mechanical breakage during handling, even minor imperfections can reduce grain quality, lower USDA grades, and significantly cut profit margins. Every year, damaged grain results in billions of dollars in lost value for farmers, grain elevators, and food processors. In this article, we’ll break down the cost of damaged grain, what causes it, and—most importantly—how to prevent it.

In this study, we’ll cover the following topics:

- What is Considered “Damaged Grain”?

- The Cost of Damaged Grain in the US

- How Grain Affects Market Value

- How Grain Damage Affects the Supply Chain

- How to Prevent Damaged Grain

- What to Do With Damaged Grain: Salvage and Recovery Options

What is Considered “Damaged Grain”?

Damaged grain refers to kernels that have become degraded due to mold, pests, moisture, or physical breakage. This includes grain that is discolored, broken, infested, or otherwise fails to meet quality standards set by buyers or regulators.

Even a small percentage of damage can push grain from a No. 2 grade to a No. 3 or No. 4—leading to steep price discounts. For example, a downgrade from No. 2 Yellow Corn to No. 4 can cost 20–50 cents per bushel. In large-volume operations, that translates into tens or hundreds of thousands in lost revenue.

Examples of damaged grain:

- Badly ground-damaged

- Badly weather-damaged

- Diseased

- Frost-damaged

- Germ-damaged

- Heat-damaged

- Insect-bored

- Mold-damaged

- Sprout-damaged

These definitions are detailed in the USDA’s Grain Inspection Handbook, which provides guidelines for inspecting and grading various types of grain.

Most Common Types of Grain Damage

Sprout Damage

Occurs when grain begins to germinate prematurely, often due to moisture exposure before harvest. Sprouted grains have altered chemical compositions, affecting their processing quality.

Mold Damage

Caused by high moisture content and poor storage conditions, leading to fungal growth. Mold can produce mycotoxins, which are harmful to both humans and animals.

Mechanical Damage

Occurs during harvesting, handling, or processing when grain is cracked or broken. This type of damage increases susceptibility to spoilage and pest infestation.

Insect Damage

Insects such as weevils and beetles can bore into kernels, compromising their integrity and making them unsuitable for consumption.

Heat Damage

Results from excessive drying temperatures, leading to discolored or burnt kernels. Heat-damaged kernels are often brittle and have reduced nutritional value.

Impact on Grain Grading

Grain grading is a critical process in the U.S. agricultural industry, ensuring that grain quality meets specific standards for marketability and safety. The United States Department of Agriculture (USDA) sets forth detailed criteria for grading various grains, focusing on factors such as damaged kernels, test weight, moisture content, and foreign material.

The USDA’s grading system classifies grain into different grades based on the extent of damage observed in the kernels. Damage can occur due to various factors (listed above).

Each type of damage affects the grain’s usability and market value, and the USDA sets specific thresholds for these damages in its grading standards.

Accurate grain grading ensures that buyers receive quality products and that sellers are compensated fairly. Exceeding the allowable limits for damaged kernels can lead to downgrading, price reductions, or rejection of grain lots. Therefore, understanding and adhering to USDA grading standards is essential for all stakeholders in the grain industry.

Takeaway: Damaged grain is defined by the USDA as any kernel that has deteriorated in a way that impacts its quality, market value, or safety—and each type of damage has specific thresholds that directly affect grain grading, pricing, and usability.

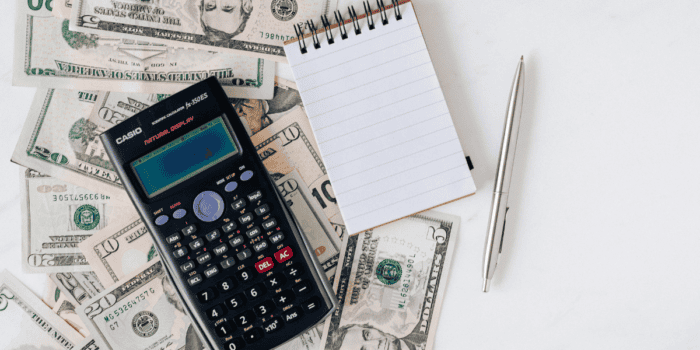

The Cost of Damaged Grain in the U.S.

Grain damage isn’t just a quality issue — it’s a financial threat that affects every stage of the supply chain. From discounted sale prices to expensive cleanup and storage losses, even a small percentage of damaged grain can result in tens of thousands of dollars in unexpected costs. And while visible issues like mold or insect damage are easy to spot, hidden losses — like insurance claim gaps or legal liability from contaminated product — can be just as costly.

Breakdown of Damage-Related Costs

- Lost sale value due to grade downgrades

- Additional handling and cleanup (labor, fuel, equipment)

- Storage loss from insect or mold infestation

- Insurance claim gaps (many damaged grain losses aren’t covered)

- Legal liability if contaminated grain enters the supply chain

Cost by Type of Damage

| Damage Type | Estimated Cost Impact |

|---|---|

| Heat Damage | Elevators often apply a discount of $0.10 per bushel for heat damage levels between 0.2% and 3%. For damage exceeding 3.1%, the discount becomes negotiable and can be significantly higher. |

| Mold/Mycotoxins | Grain with mold damage may receive a “sample” grade, leading to a discount of 8.5%. Additional discounts may apply if the grain has a musty, sour, or otherwise objectionable odor. |

| Insect Damage | While specific per-bushel discounts vary, significant insect damage can lead to substantial price reductions or even rejection of the grain lot. |

| Sprout Damage | Specific discounts for sprout damage vary by buyer and region, but significant sprouting can lead to substantial price reductions or rejection. |

| Mechanical Damage | While specific per-bushel discounts vary, excessive mechanical damage can lead to significant price reductions. |

National Economic Impact

- Wheat Disease Losses: In 2023, wheat diseases led to an estimated loss of 49.5 million bushels across 28 U.S. states and Ontario, Canada, valued at nearly $360 million.

- Aflatoxin in Corn: Aflatoxin contamination in corn, exacerbated by climate change, could cause annual losses ranging from $52.1 million to $1.68 billion in the U.S.

- Natural Disasters: Major disasters and severe weather events in 2023 resulted in over $21.94 billion in crop and rangeland losses, with a significant portion attributed to grain damage.

Regional Case Studies

- Midwest Flooding (2019): Flooding in the Midwest damaged an estimated 5 to 10 million bushels of corn and soybeans, valued between $17.3 million and $34.6 million.

- Derecho in Iowa (2020): The 2020 derecho destroyed approximately 57 million bushels of grain storage in Iowa, with repair and replacement costs estimated at over $300 million.

Grain damage can quietly drain profitability through lost sale value, storage issues, and costly downgrades. But with the right handling, storage, and salvage strategies, much of this damage is preventable — or at least recoverable.

Takeaway: Grain damage leads to significant and often preventable financial losses — from direct price reductions and rejections to hidden costs like insurance gaps and liability — adding up to billions of dollars annually across the U.S. grain industry.

How Grain Damage Affects Market Value

Grain damage directly impacts market value by lowering the grain’s USDA grade, which in turn influences pricing, buyer interest, and final usability. Even minor imperfections—such as cracked kernels, mold, or heat damage—can downgrade a load of grain from U.S. No. 1 to a lower grade, triggering steep financial penalties or outright rejection from buyers.

Downgrades Equal Dollar Losses

Each USDA grain grade corresponds to an expected market price. When grain is downgraded due to damage, the per-bushel price drops significantly.

For example:

- Corn that is graded U.S. No. 1 typically commands the highest price

- If that same corn is downgraded to U.S. No. 3 due to 7% total damage, the price could drop to $0.30 to $0.70 per bushel depending on market demand and local elevator penalties.

- In a 50,000-bushel load, that could mean $15,000–$35,000 in losses just from damage-related discounting.

Common Market Penalties

Grain buyers—including ethanol plants, feed mills, exporters, and grain elevators—use a combination of USDA grade and internal specs to determine value.

Here are common ways damaged grain is penalized:

- Price Dockage: Buyers deduct a set amount per bushel for excess damaged kernels.

- Blending Limits: Some facilities will blend lower-grade grain with higher-grade stocks, but often at a reduced price.

- Rejection Risk: Grain that exceeds acceptable damage thresholds—especially for mold or toxins—may be completely rejected.

- Increased Handling Costs: Buyers may charge extra if your grain requires special handling, drying, or cleaning.

Invisible Losses Add Up

Not all financial impacts are reflected in the sale price. Damaged grain also introduces indirect costs.

Such as:

- Storage losses from spoilage or insect activity

- Increased drying time due to moisture

- Labor and fuel costs to reprocess or transport unsellable grain

- Lost premiums on contracts for high-grade grain (e.g., food-grade or export)

Even if some damaged grain can be salvaged, the cost of recovery—both in time and money—can cut deeply into your margins.

Takeaway: Quality issues aren’t just cosmetic — they’re costly. Preventing, detecting, and addressing grain damage early is essential for protecting your bottom line.

How Damaged Grain Affects the Supply Chain

The effects of damaged grain ripple far beyond the farm — touching every link in the agricultural supply chain. Poor grain quality not only cuts into farmer profits but also creates downstream inefficiencies and added costs for handlers, processors, and end-users.

For Producers

- Farmers face direct revenue losses due to grade downgrades, rejected loads, or emergency salvage costs.

- Damaged grain often disqualifies producers from premium markets or export contracts, reducing competitiveness.

For Grain Elevators and Storage Facilities

- Elevators must spend more time sorting, drying, and discarding damaged kernels, increasing labor and equipment wear.

- Spoilage-prone grain puts bins at higher risk of fire, infestation, or full-system clean out, leading to costly downtime.

- Quality issues disrupt blending strategies and limit inventory flexibility.

For Feed Mills and Food Processors

- Inconsistent or low-quality grain may force buyers to seek alternative suppliers, often at higher cost or farther distances.

- Mycotoxins or insect infestations can render grain unusable for food or feed applications, creating waste and regulatory risk.

- Processors may need to invest in more stringent incoming quality checks, slowing production timelines.

For the Supply Chain Overall

- Damaged grain leads to more shrink, more waste, and less usable output per acre.

- Transportation costs increase when salvaged or downgraded grain requires special routing or cannot be accepted at destination.

- Trust in the grain supply chain declines — impacting contracts, pricing, and long-term relationships across the industry.

Takeaway: Damaged grain disrupts efficiency, increases waste, and undermines profitability across the entire agricultural economy.

How to Prevent Damaged Grain

While some level of grain loss is inevitable, the majority of damage is preventable. Here’s how growers and handlers can reduce the risk:

Harvest at the Right Time

- Every grain (corn, soybeans, wheat, barley, sorghum, etc.) has an optimal moisture window for harvest to prevent spoilage or damage.

- Use calibrated moisture meters to make informed decisions.

- Harvesting too wet → mold, sprouting

- Harvesting too dry → mechanical damage from brittleness

Use Gentle Handling Practices

- Slow down augers and conveyors.

- Avoid dropping grain from excessive heights into bins or trucks.

- Use grain cushions where appropriate to reduce impact.

Maintain Proper Storing Conditions

- Keep bins clean and sealed before filling.

- Use aeration systems to maintain consistent temperature and moisture.

- Monitor regularly with temperature cables and CO2 sensors if possible.

Implement a Monitoring Routine

- Check stored grain weekly, especially during temperature changes.

- Address hotspots, crusting, or insect activity early.

Plan Preventative Maintenance

- Service handling equipment before harvest to avoid breakdowns and kernel damage.

- Calibrate dryers and monitors to avoid over or under-drying

Get the PDF: How to Prevent Damaged Grain

Takeaway: Most grain damage is preventable — and by managing harvest timing, handling practices, storing conditions, and maintenance practices, producers can protect grain quality, avoid costly downgrades, and maintain market value.

What to Do With Damaged Grain: Salvage and Recovery Options

Grain damage can happen quickly and without warning — whether due to fire, weather, or equipment failure. That’s where West Side Salvage steps in. Our team provides rapid-response grain salvage services to help you recover as much value as possible from compromised storage conditions.

We also offer professional damage assessments to evaluate the condition of your grain and identify whether it can be dried, blended, cleaned, or must be disposed of. Our experts help you make the best decision for both safety and financial return.

In addition, we provide full-service bin cleaning and maintenance, removing spoiled grain, blockages, and debris that can contribute to future spoilage or pest problems. Clean bins are critical for safe, long-term storage.

Finally, West Side Salvage offers preventive support — including consulting on best practices for grain handling, drying, and storage — so you can minimize the risk of damage before it becomes a costly problem.

Conclusion

Grain damage isn’t just a nuisance — it’s a serious financial risk that affects every stage of grain production, from the field to final sale. Whether it’s heat, mold, insects, or handling issues, even minor damage can lead to major losses in grade, value, and revenue.

By understanding the true cost of grain damage and taking steps to prevent it, producers can better protect their bottom line.

And when damage does occur, West Side Salvage is ready to help with fast, professional salvage services, damage assessments, and bin maintenance support — so you can recover quickly and keep your operation moving.

References

- United States Department of Agriculture. Grain Inspection Handbook: Book II – Grain Grading Procedures. USDA AMS

- Encyclopædia Britannica. Germination – Plant Physiology. Britannica.com

- World Health Organization. Mycotoxins. WHO Fact Sheet

- Wheaton Grain. FCCP Grading Schedule. wheatongrain.com

- Iowa State University Extension and Outreach. Discount Schedule for Grain with Abnormal Quality. extension.iastate.edu

- Crop Protection Network. Wheat Disease Loss Estimates from the United States and Ontario, Canada – 2023. cropprotectionnetwork.org

- Mitchell, N. J., et al. Potential Economic Losses to the USA Corn Industry from Aflatoxin Contamination. NIH / PMC

- American Farm Bureau Federation. Major Disasters and Severe Weather Caused Over $21 Billion in Crop Losses in 2023. fb.org

- Iowa Department of Agriculture and Land Stewardship. Letter to USDA on Derecho-Related Crop Damage and Harvest Challenges. iowaagriculture.gov