The Most Effective Silo Cleaning Methods

Keeping silos clean isn’t just about looks, it’s about protecting grain quality, ensuring worker safety, and extending the lifespan of your storage facility. When silos aren’t maintained, blockages, mold, and even dangerous grain entrapments can occur. In this blog, we’ll cover the most effective silo cleaning methods used in agriculture and industrial storage, along with tips for choosing the right solution for your operation.

✓ METHOD #1

Manual Cleaning

Manual silo cleaning involves workers physically entering the silo to sweep, shovel, or break apart hardened grain and residue.

- Best for: Smaller silos or light buildup.

- Advantages: Low equipment cost and straightforward.

- Drawbacks: Time-intensive and poses serious safety risks such as entrapment, falls, and dust inhalation.

✓ METHOD #2

Bin Whip/Pneumatic Whip Systems

Bin whip systems are powered by compressed air and use rotating whips to dislodge compacted or crusted grain.

- Best for: Medium-to-large silos and significant buildup.

- Advantages: Operators remain outside of the silo, reducing the chance of accidents.

- Drawbacks: The pneumatic whip is effective at restoring storage capacity and breaking up tough blockages.

✓ METHOD #3

Air Cannons & Vibrators

Air cannons deliver sudden bursts of compressed air, while vibrators shake silo walls to keep material flowing.

- Best for: Preventing buildup before it hardens.

- Advantages: Automated systems reduce the need for manual interventions.

- Drawbacks: Less effective for major blockages or out-of-condition grain.

✓ METHOD #4

Water Blasting (Hydrocleaning)

This method uses high-pressure water jets to wash away residue and compacted grain.

- Best for: Silos storing sticky materials or facilities needing deep sanitization.

- Advantages: No need for workers to enter the silo; it’s thorough and highly effective.

- Drawbacks: Creates wastewater that must be properly managed.

✓ METHOD #5

Chemical Cleaning

Certain industrial silos require chemical agents to break down hardened materials or contamination.

- Best for: Silos storing non-food materials such as cement, minerals or chemicals.

- Advantages: Effective for stubborn residue.

- Drawbacks: Limited use in grain or food-grade storage due to contamination risks.

✓ METHOD #6

Rotary/Bin Drill Systems

Rotary heads or bin drills use compressed air to drive a cutting or boring tool into hardened grain and blockages.

- Best for: Severe bridging, “out-of-condition” grain, or fully plugged silos.

- Advantages: Extremely effective at breaking through compacted or caked material.

- Drawbacks: Must be operated carefully to prevent structural damage.

✓ METHOD #7

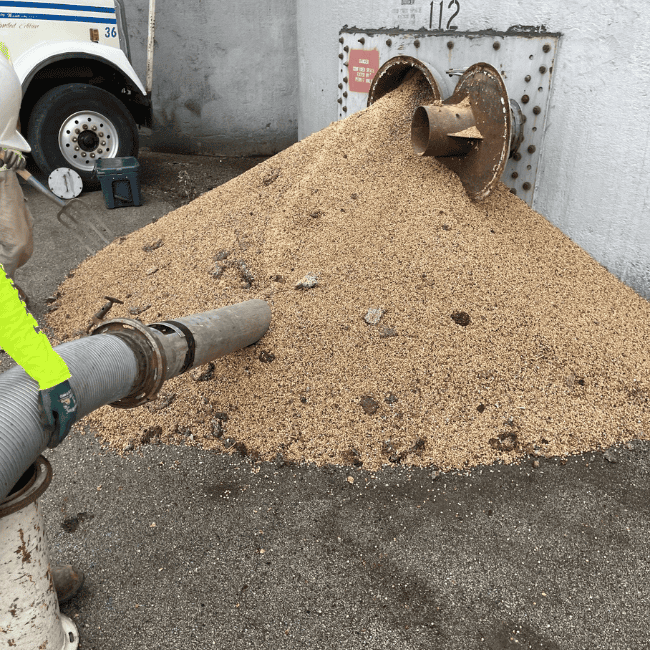

Vacuum/Pneumatic Conveyance Systems

Industrial vacuum systems are used to safely remove loose grain, dust, and fines from inside silos.

- Best for: Dust removal, light debris, or as a finishing step after other cleaning methods.

- Advantages: Reduces dust accumulation and explosion risk; OSHA-compliant.

- Drawbacks: Less effective on hardened blockages.

Need A Silo Cleaning?

Regular silo cleaning prevents costly blockages, grain loss, and downtime. West Side Salvage has the tools and expertise to keep your bins clean and your business running smoothly.

Choosing the Right Cleaning Method

- Assess the silos size, condition and stored material.

- Identify the type of buildup (light dust, hardened crust, sticky residue).

- Consider safety requirements and worker entry risks.

- Match your needs with the most effective cleaning method.

Benefits of Proper Silo Cleaning

- Preserves grain quality and reduces spoilage.

- Extends silo lifespan by preventing corrosion and stress damage.

- Improves worker safety by lowering the chance of blockages or entrapments.

- Cuts emergency repair costs by catching issues early.

Fun Fact: The U.S. saw nine grain dust explosions in 2024, but thanks to safety and cleaning improvements, there were only two injuries and zero fatalities. (Purdue University)

Silo cleaning is not a one-size-fits-all process. The right method depends on your facility’s size, the material being stored, and the severity of buildup. From manual labor to advanced pneumatic and hydro systems, each approach has its place. What matters most is safety, prevention, and having the right partner by your side.

At West Side Salvage, we specialize in safe, efficient silo cleaning and emergency response services. While not every method listed here is part of our service offering, our team has the expertise to assess your situation and apply the right tools to clear blockages, restore capacity, and reduce risks.