Why Grain Bin Maintenance Delivers Real ROI

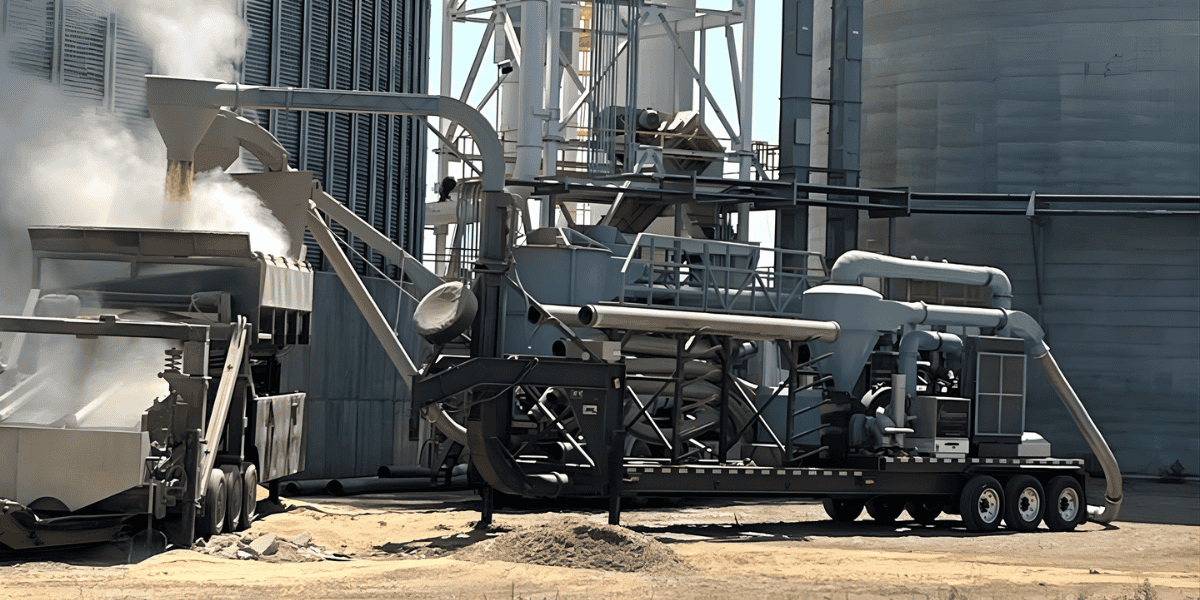

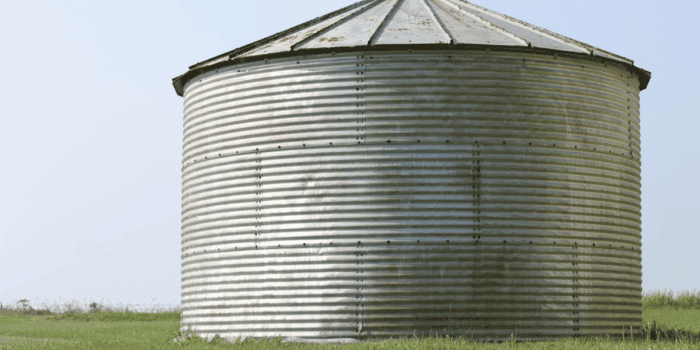

Grain storage is one of the most important long-term investments on a farm or in a commercial grain operation. But the value of that investment depends entirely on how well it’s maintained. Well-kept bins protect grain quality, prevent costly downtime, reduce safety risks, and give farmers the flexibility to sell when markets are right. Poorly maintained bins do the opposite, they leak value every single day.

Want to work with the best?

Regular maintenance helps prevent spoilage, reduce downtime, and extend the life of your bins and equipment. West Side Salvage works with operations of all sizes to inspect, maintain, and address issues before they turn into costly problems.

Why Grain Bin Maintenance Matters

Most grain problems start small. A loose seal, a worn fan belt, fines left from last season, or a hidden leak can slowly create moisture pockets or hot spots. Over time, these small issues can become:

- Higher spoilage risk

- Insect activity

- Crusting or bridging

- Reduced airflow

- Structural damage

- Safety hazards

Maintenance stops these issues early, keeping storage systems reliable and grain quality stable.

❗️According to the USDA, temperature and moisture conditions directly affect mold growth, insect activity, and overall grain loss. Routine maintenance that keeps aeration and sealing systems working properly helps prevent these issues before they impact grain quality or value.

What Research Shows About Grain Storage Maintenance

📉 Proper Maintenance Prevents Spoilage and Value Loss

University of Minnesota Extension emphasizes that routine care is essential for minimizing grain losses. In their guidance on stored-grain management, they state that farmers should “Properly maintain and use grain handling equipment, drying systems and storage structures.”

This includes cleaning debris, checking seals, maintaining equipment, and ensuring airflow systems are working, a strong argument that maintenance directly protects grain value.

🛡️ Aeration Maintenance Protects Grain Quality

USDA-ARS research shows that temperature and moisture control affect every biological and insect threat inside a bin. “All organisms responsible for losses in stored grain and seed are affected by the condition (temperature and moisture) of the material.”

If aeration fans aren’t maintained, monitored, and cleaned, temperature stratification and moisture migration can quickly develop into spoilage.

🐜 Poor Maintenance Increases Pest Risk

Ohio State University Extension makes it clear: pests thrive where maintenance is lacking. “Prevention is the key… Excess moisture and high temperature are the primary causes of spoilage.”

Good sealing, debris removal, and routine inspections are essential to keeping pests out, and grain quality intact.

The ROI of Grain Storage Maintenance

While maintenance itself isn’t usually broken out in published ROI analyses, several studies show how well-managed storage leads to stronger returns.

💲Capturing Better Prices

Farm Business Network (FBN) modeled a 600-acre corn operation storing grain instead of selling at harvest. The operation gained $81,000 in value because the grain stayed in condition long enough to hit better market timing.

This only works if the grain stays dry and cool, making maintenance a key part of the value chain.

📈 High Long-Term ROI Potential

A 2025 storage ROI study showed:

- 67–200% ROI over 10 years when grain quality is preserved

- –18% ROI when grain quality suffers or storage systems are poorly managed

Good maintenance is the difference between those outcomes.

🌾 Harvest Efficiency Matters

GRDC’s storage economics report found that efficient, well-maintained storage reduces bottlenecks and improves harvest timing. In one example, improved efficiency produced a 9% ROI with an 11-year payback. Every delay prevented adds up.

Where Maintenance Creates Real Financial Value

A well-maintained storage system delivers returns in several ways:

Avoiding Spoilage and Quality Loss

Spoiled grain can lose 10–30% or more of its value. Maintenance helps prevent:

- Mold growth

- Hot spots

- Moisture migration

- Crusting

Reducing Quality Discounts

Most grain buyers penalize for:

- Low test weight

- High moisture

- Insects

- FM/dockage

- Mold

Minimizing Emergency Repairs

When maintenance is deferred, problems turn into:

- Failed fans

- Damaged floors

- Plugged or unsafe bins

- Structural failures

Extending the Life of Storage Equipment

Maintaining a bin’s roof, panels, foundation, and mechanical systems prevents corrosion, stress cracks, and premature failure.

What Regular Grain Storage Maintenance Involves

Before Filling

- Clean out leftover grain

- Check seals, doors, and vents

- Inspect bin walls, roof, and foundation

- Test aeration fans and heaters

- Verify sump and floor transitions

- Review temperature cables and sensors

During Storage

- Monitor grain temperature weekly

- Run fans based on weather conditions

- Watch for crusting or bridging

- Check for leaks and condensation

- Inspect for pest activity

After Emptying

- Complete a full clean-out

- Inspect the full structure

- Repair cracks or corrosion

- Service fans and motors

- Document issues for planning

A Simple ROI Formula for Maintenance

You can calculate your storage maintenance ROI with:

ROI = (Losses avoided + Price gains + Efficiency improvements – Maintenance cost) ÷ Maintenance cost

Conclusion

Regular grain storage maintenance pays off by protecting grain quality, reducing spoilage risk, and keeping your operation running smoothly. The research makes it clear that well-maintained bins support better market timing, fewer quality discounts, and a stronger long-term return compared to systems that are ignored or repaired only when something goes wrong.

Staying proactive with inspections and clean-outs is the simplest way to safeguard your grain and your investment, and when you do need extra support or repairs, West Side Salvage is there to help keep your storage systems safe, reliable, and ready for the next season.