Grain Fires and Explosions: Yearly Trends, Causes, and Prevention

Grain bin fires and explosions are persistent hazards in the agriculture and grain handling industries, posing serious risks to workers, facilities, and the supply chain. While these incidents may not always make national headlines, they do happen and they can have devastating consequences—causing injuries, fatalities, and millions of dollars in damage each year.

In this study, we’ll cover the following topics:

- Annual Trends: Frequency, Facility, State, and Commodity.

- Causes & Contributing Factors: Malfunctions, Human Activities, & Storage Conditions

- Impact of Explosions: Safety and the Economy

- Industry’s Response: Regulations, Technological Improvements, Best Practices, & Training Programs

The Frequency of Grain Bin Fires and Explosions

According to Purdue University’s annual summary, the United States experienced nine grain dust explosions in 2024. These incidents occurred across nine different states, impacting a variety of facilities, including flour and feed mills, grain elevators, an ethanol plant, and a corn processing plant.

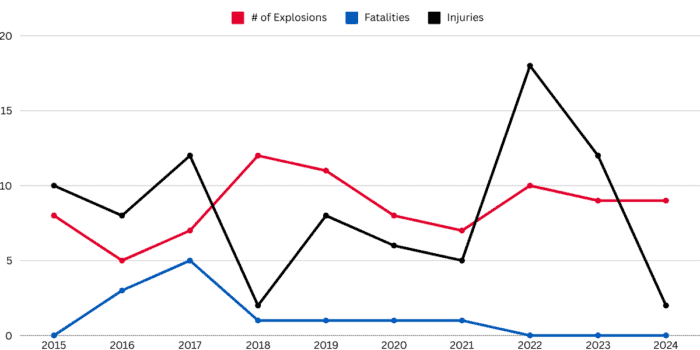

Trends Over 10 Years

Over the past decade, the national average for grain dust explosions has been 8.6 per year, marking a noticeable decline from the previous 10-year average of 10 per year. This downward trend suggests that improved safety protocols and industry awareness may be helping to reduce the overall frequency of incidents.

In terms of injuries, recent years have shown a significant reduction. After recording 18 injuries in 2022 and 12 in 2023, the number dropped to just two in 2024. This decline likely reflects ongoing improvements in safety measures, dust control strategies, and facility maintenance practices, which are helping to mitigate the severity of explosions when they do occur.

| Year | Number of Explosions | Fatalities | Injuries |

|---|---|---|---|

| 2015 | 8 | 0 | 10 |

| 2016 | 5 | 3 | 8 |

| 2017 | 7 | 5 | 12 |

| 2018 | 12 | 1 | 2 |

| 2019 | 11 | 1 | 8 |

| 2020 | 8 | 1 | 6 |

| 2021 | 7 | 1 | 5 |

| 2022 | 10 | 0 | 18 |

| 2023 | 9 | 0 | 12 |

| 2024 | 9 | 0 | 2 |

| Ten Year Total | 86 | 12 | 83 |

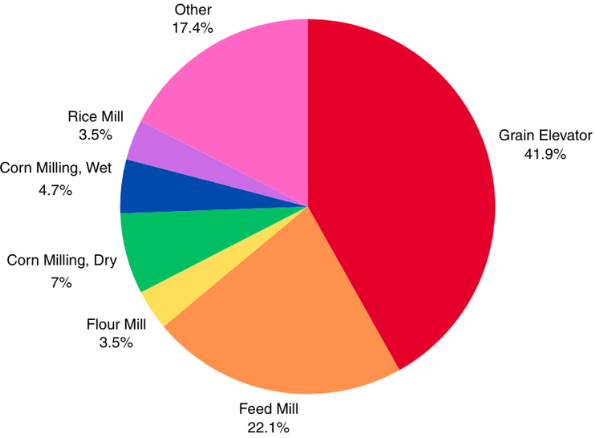

Fires & Explosions by Facility (2015-2024)

| Year | Grain Elevator | Feed Mill | Flour Mill | Corn Milling, Dry | Corn Milling, Wet | Rice Mill | Other |

|---|---|---|---|---|---|---|---|

| 2015 | 2 | 4 | 0 | 0 | 0 | 0 | 2 |

| 2016 | 2 | 1 | 2 | 0 | 0 | 0 | 0 |

| 2017 | 5 | 0 | 0 | 1 | 0 | 0 | 1 |

| 2018 | 8 | 2 | 0 | 0 | 0 | 0 | 2 |

| 2019 | 4 | 4 | 0 | 1 | 0 | 0 | 2 |

| 2020 | 4 | 1 | 0 | 0 | 1 | 1 | 1 |

| 2021 | 4 | 1 | 0 | 0 | 1 | 0 | 1 |

| 2022 | 2 | 2 | 0 | 2 | 0 | 2 | 2 |

| 2023 | 2 | 0 | 1 | 2 | 1 | 0 | 3 |

| 2024 | 3 | 4 | 0 | 0 | 1 | 0 | 1 |

| Ten Year Total | 36 | 19 | 3 | 6 | 4 | 3 | 15 |

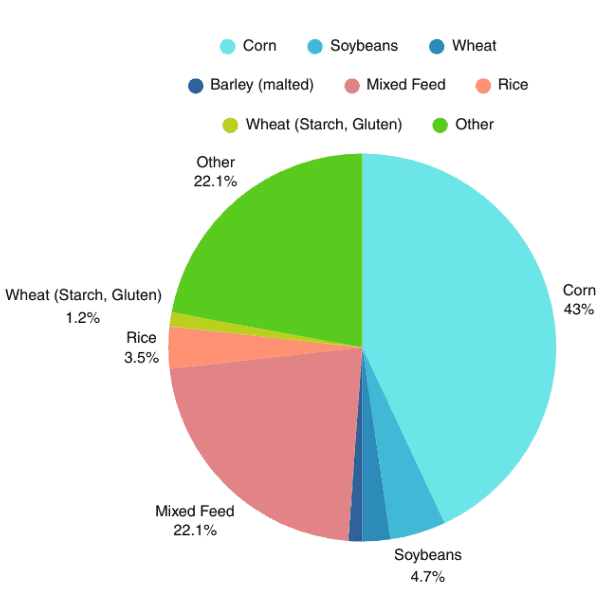

Fires & Explosions by Commodity (2015-2024)

| Year | Corn | Soybeans | Wheat | Barley (malted) | Mixed Feed | Rice (Bran, Flour, Hulls) | Wheat (Starch, Gluten) | Other |

|---|---|---|---|---|---|---|---|---|

| 2015 | 2 | 0 | 0 | 1 | 3 | 0 | 0 | 2 |

| 2016 | 1 | 0 | 0 | 0 | 1 | 0 | 1 | 2 |

| 2017 | 6 | 0 | 0 | 0 | 0 | 0 | 0 | 1 |

| 2018 | 6 | 0 | 0 | 0 | 4 | 0 | 0 | 2 |

| 2019 | 5 | 1 | 0 | 0 | 3 | 0 | 0 | 2 |

| 2020 | 2 | 0 | 1 | 0 | 3 | 1 | 0 | 1 |

| 2021 | 3 | 0 | 0 | 0 | 3 | 0 | 0 | 1 |

| 2022 | 2 | 1 | 0 | 0 | 1 | 2 | 0 | 4 |

| 2023 | 5 | 2 | 1 | 0 | 0 | 0 | 0 | 1 |

| 2024 | 5 | 0 | 0 | 0 | 1 | 0 | 0 | 3 |

| Ten Year Total | 37 | 4 | 2 | 1 | 19 | 3 | 1 | 19 |

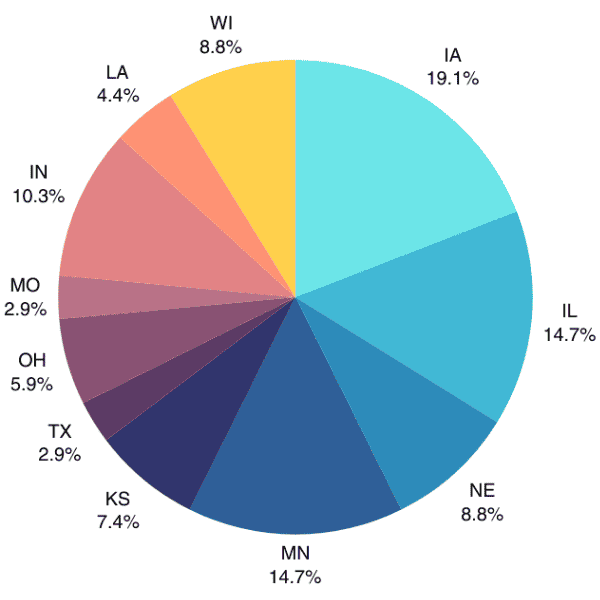

Fires & Explosions by State (2015-2024)

| Year | IA | IL | NE | MN | KS | TX | OH | MO | IN | LA | SD | WI |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2015 | 0 | 1 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 0 | 0 | 0 |

| 2016 | 1 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 1 | 0 | 0 | 1 |

| 2017 | 1 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 2 |

| 2018 | 2 | 2 | 1 | 2 | 1 | 1 | 0 | 0 | 1 | 1 | 0 | 1 |

| 2019 | 3 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | 1 | 0 | 0 | 1 |

| 2020 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 0 |

| 2021 | 1 | 0 | 0 | 2 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 |

| 2022 | 1 | 1 | 1 | 0 | 1 | 0 | 1 | 0 | 0 | 2 | 0 | 0 |

| 2023 | 2 | 3 | 0 | 3 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 |

| 2024 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 1 |

| Ten Year Total | 13 | 10 | 6 | 10 | 5 | 2 | 4 | 2 | 7 | 3 | 0 | 6 |

Historical Analysis

Prior to the establishment of OSHA’s Grain Handling Facilities Standard in 1988, the United States experienced a higher frequency of grain dust explosions, often with more severe consequences. During the 1970s and early 1980s, there were approximately 20 or more explosions annually, many resulting in significant fatalities and injuries. Notably, between December 1977 and January 1978, five separate explosions led to 62 worker deaths and 53 injuries. These disasters prompted the implementation of stricter safety measures and protocols, leading to a decline in incident frequency. However, while the number of occurrences has decreased, such incidents have not been entirely eliminated.

Causes and Contributing Factors

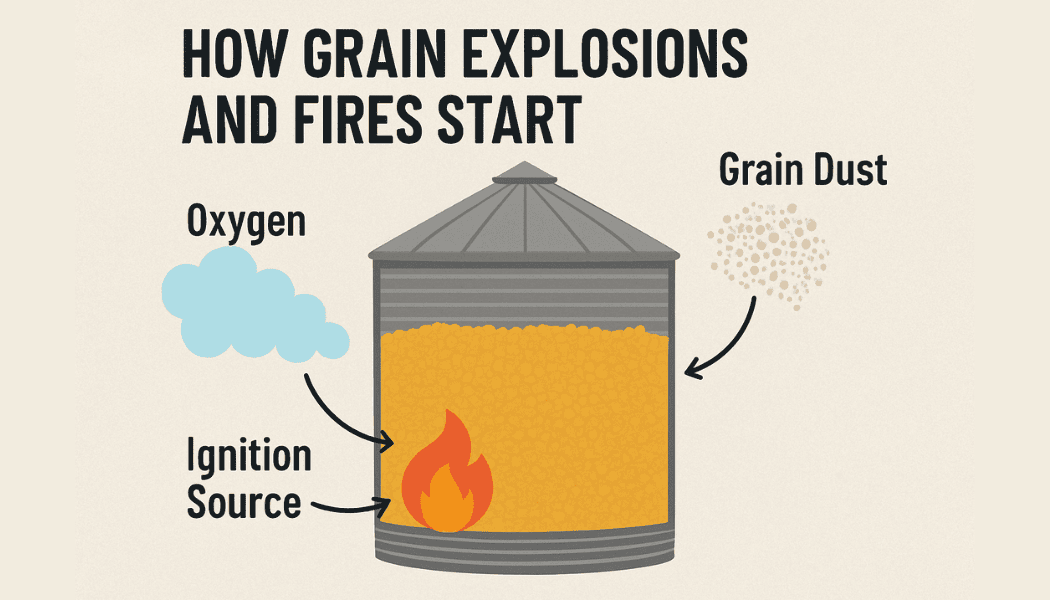

Understanding the causes of grain bin fires and explosions is crucial for preventing these dangerous incidents. Several factors can contribute to ignition, with some of the most common including equipment malfunctions (such as overheated bearings, friction, and sparks), human activities (like welding, cutting, or maintenance work), and storage conditions (such as moisture buildup leading to smoldering grain).

Beyond these direct ignition sources, external factors like weather conditions, harvest size, and poor industry practices also play a role. Inadequate dust management, lack of proper maintenance, and improper grain handling can create the perfect environment for fires and explosions to occur.

For a more detailed breakdown of the causes and risks associated with grain bin and silo fires and explosions, check out our blog: Silo Fires and Explosions; Why Do They Happen?

Economic and Safety Impacts

Grain fires and grain explosions pose significant economic and safety risks to the agricultural and grain handling industries. These incidents can result in millions of dollars in damages, cause serious injuries or fatalities, and disrupt grain supply chains, making safety a top priority for facility operators.

Economic Costs:

- Facility Damage and Downtime– These explosions can destroy facilities and lead to very costly repairs and a tremendous amount of downtime that contributes to lost productivity.

- Lost Inventory– When these fires and explosions occur, they will destroy any product that was in the bin, leading to great financial loss for distributors and producers. Burned grain can not be salvaged.

- Regulatory Fines and Legal Consequences– Any companies that were not following OSHA grain handling safety regulations are at risk of being fined and having legal action brought onto them.

- Increased Insurance Costs– Facilities that have a history of explosions or disasters are likely to see their premiums increase significantly.

- Supply Chain Disruptions– If a fire or explosion occurs at a facility that is a key storage or processing facility, it can cause issues for other local and national grain supply chains ultimately resulting in price fluctuations.

Worker Safety and Human Impact:

- Injuries and Fatalities– While the number of fatalities has decreased in recent years, serious injuries still occur (18 in 2022, 12 in 2023, and four in 2024).

- Respiratory Hazards– When fires and explosions occur, they produce toxic fumes and fine dust particles that are harmful to breathe in. These can result in serious lung damage as well as respiratory diseases.

- Psychological Impacts– A disaster as serious as a bin fire or explosion can be very traumatic to experience and can cause long-term phycological impacts on a person, which in return can affect their ability to return to work.

How the Industry is Responding

In response to ongoing grain bin fires and explosions, the agriculture and grain handling industries have made significant improvements in safety measures, dust control practices, and regulatory compliance. While explosions still occur annually, enhanced awareness and technological advancements have helped reduce the severity and frequency of incidents compared to previous decades.

Stricter Regulations

Improved Dust Control and Ventilation Systems

- Cyclone dust collectors and baghouses

- High-efficiency ventilation systems

- Regular deep-cleaning schedules

- “No Accumulation” policies

Advanced Explosion Prevention Technology

- Automated bearing temperature monitoring

- Spark detection and suppression systems

- Explosion venting and suppression systems

- Electrostatic grounding equipment

Safer Grain Handling and Maintenance Practices

- Slower grain movement speeds

- Enclosed conveyors instead of open belt systems

- “Hot work permits”

- Thermal monitoring in storage bins

Industry-Wide Education and Training Programs

- Worker safety training on explosion hazards and prevention

- Emergency response drills for fire and explosion incidents

- Workshops on best practices for dust management and safe grain handling

Conclusion

While the number of grain bin fires and explosions has declined over the years, these incidents still pose significant risks to workers, facilities, and the agricultural supply chain. The primary causes—grain dust accumulation, equipment malfunctions, and poor storage conditions—are largely preventable with proper safety measures, maintenance, and training.

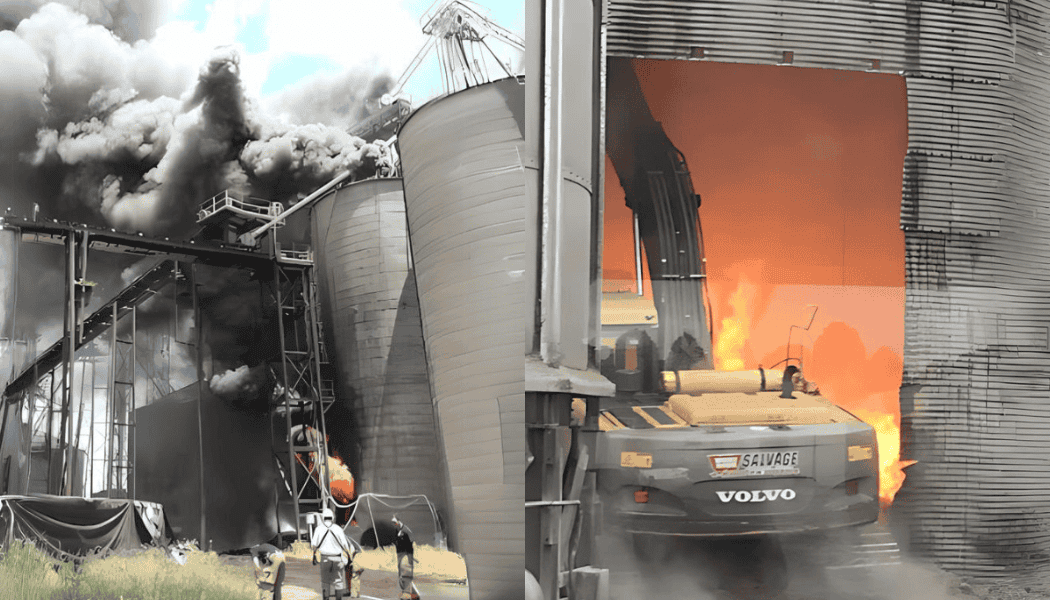

When a grain explosion or fire occurs, the damage can be devastating, often leaving behind collapsed structures, damaged silos, and massive grain spills. This is where West Side Salvage can help. As an industry leader in grain salvage, bin cleanup, and emergency response, West Side Salvage specializes in recovering spilled or damaged grain, repairing fire-damaged bins, and minimizing losses after an explosion. Their team has the expertise and equipment needed to safely remove debris, salvage usable grain, and restore operations as quickly as possible.

By staying proactive with dust control, safety training, and proper equipment maintenance, facilities can prevent most explosions before they happen. But when disaster strikes, West Side Salvage is the trusted partner to help recover quickly and get operations back on track. Contact us today to learn more about emergency grain salvage and fire recovery services.

References:

- Purdue University. (2024). Grain Dust Explosions 2024. Purdue University Fire and Explosion Research. Retrieved from https://engineering.purdue.edu/FFP/research/dust-explosions/Grain_Dust_Explosions_2024.pdf

- Occupational Safety and Health Administration (OSHA). Standard Number 1910.272 – Grain Handling Facilities Regulations. Retrieved from https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.272

- National Fire Protection Association. (2024). NFPA 61: Standard for the Prevention of Fires and Dust Explosions in Agricultural and Food Processing Facilities. Retrieved from https://www.nfpa.org/codes-and-standards/nfpa-61-standard-development/61

- Dust Safety Science. NFPA Housekeeping Analysis. Retrieved from https://dustcenter.org/nfpa-housekeeping-analysis.html#:~:text=Dust%20layers%20limited%20to%20an,Permitted

- Environmental Protection Agency (EPA). Hot Work Definition and Requirements. Retrieved from https://www.epa.gov/rmp/hot-work-definition-and-requirements#:~:text=Hot%20work%20means%20work%20involving,hot%20work%20operations%20are%20completed